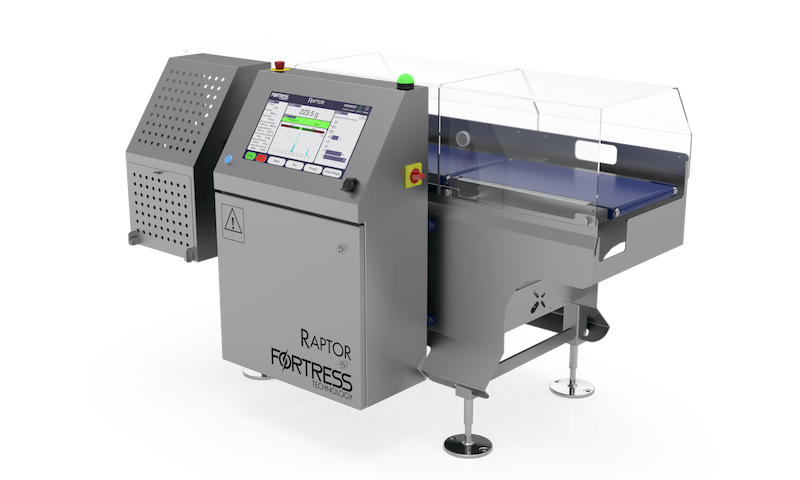

Raptor by Fortress

Since 1996, Fortress Technology has created custom manufactured equipment and software for thousands of clients around the world. Designed with longevity in mind, Fortress’s equipment is easily serviced and upgraded – it will never become obsolete – saving thousands over the lifespan of the system. With a focus on responsive customer service, Fortress Technology is the only choice for your inspection needs.

The success of Fortress is based on Innovative Leading-Edge Design, Straight Forward and Simple to use Operator Controls, Rugged and Reliable Construction and Exceptional Performance.

For more information, please contact us.

Raptor Checkweigher

- The Raptor is a highly accurate, fully integrated checkweighing system, specifically designed for high care food production environments. The Raptor is employed to verify the weight of each product and reject non-conforming packs. The system has been designed, engineered, and constructed to the highest care/food grade engineering standards. It is capable of processing packaged products up to 8 kg. Raptor can be used at any stage in your process to inspect safely, reliably, and accurately 100% of your products. Belt widths: 200 mm, 300 mm, 400 mm Weighing capacity: 50 g to 8 kg

Raptor XL Checkweigher

- The Raptor XL is a highly accurate, fully integrated caseweighing system, specifically designed to suit any large bag or case application. The Raptor XL is employed to verify the weight of each product within tolerances or using another weighing system. The Raptor XL has been designed, engineered, and constructed to the highest care/food grade engineering standards. Raptor XL can be used at any stage in your process to inspect safely, reliably, and accurately 100% of your products. Built-in data collection software with USB data transfer, OPC-UA and Ethernet/IP facilities (optional) allow for ease of production performance tracking and improvement of operational efficiency. Belt width: 500 mm Weighing capacity: Regular:25kg, Heavy-Duty:50kg

Raptor Combination System

- The Raptor is a highly accurate, fully integrated checkweighing and metal detection combination system, specifically designed for high care food production environments. The Raptor is employed to verify the weight and inspect for metal contaminants of each product and reject non-conforming packs. The system has been designed, engineered and constructed to the highest care/food grade engineering standards. It is capable of processing packaged products. Raptor can be used at any stage in your process to safely, reliably and accurately inspect 100% of your products. Multiple end of line inspection processes can now be carried out, and controlled, within one highly compact system. Belt widths: 200mm, 300mm, 400mm Weighing capacity: 50 g to 8 kg

Key Features for All Raptor Weighing Systems

SIMPLE AND ROBUST

- Heavy duty IP65 grade equipment. Robust, precision made, lift-out conveyors. No tools. No fuss.

- EFFICIENT OUT OF TOLERANCE REJECTION

- Available kicker, air-blast and other reject configurations accurately removes over or under weight product from production flow whilst minimizing product giveaway and protecting brand integrity.

- EASY TO USE

- Simple HMI interface ensures user-friendly operation and enhances process efficiencies. Latest generation 18.5″ capacitive industrial touchscreen displays important data and reduces training time.

- SANITARY DESIGN

- Hygienic design supports sanitation processes with easy clean, sloped surfaces to promote water runoff and speed up drying time.

- LOW MAINTENANCE

- Intelligent conveyor design allows for complete removal and disassembly of conveyor components for maintenance access and cleaning in seconds.